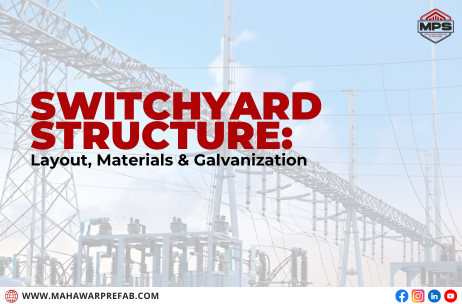

A switchyard is the last-mile interface that connects power generation or an industrial plant to the grid. It houses high-voltage equipment, provides isolation, protection, and metering, and ensures safe maintenance access — while withstanding sun, rain, dust, wind, and corrosive atmospheres for decades.

Where Switchyards Are Used

1. Hydropower

- Evacuates power from generators via step-up transformers to 132/220/400 kV.

- Terrain-driven layouts (valleys, riverbanks) with higher lightning and mist exposure; clear crane routes for transformer movement are critical.

2. Solar & Wind Parks

- Collects multiple inverter/WTG feeders into a pooling substation (33/66/110 kV), then steps up to grid voltage.

- Emphasis on modular, expandable bays and fast installation to match project commissioning timelines.

3. Process & Heavy Industry (Steel, Cement, Refineries, Data Centers)

- Integrates incoming utility supply with plant distribution.

- Often needs fully or partially enclosed structures for dust/noise control and improved ingress protection.

What a Typical Switchyard Looks Like

While sizes and voltages vary, most switchyards include:

- Equipment Bays: Transformer, circuit breaker, isolator, CT/PT, surge arrester, busbars, gantry portals.

- Bus Arrangement: Single bus, double bus, main-and-transfer, or ring bus — selected for reliability and maintenance flexibility.

- Foundations & Plinths: RCC pedestals for steel gantries/equipment; transformer blast walls where required.

- Structures: Steel gantry columns and beams to support conductors/busbars and maintain electrical clearances.

- Cable Management: Trenches with covers, gland plates, and marshaling kiosks; well-planned routes to the control room.

- Earthing Grid: Buried conductors, risers, test links; all steel tied into the grid for personnel safety.

- Weather Protection: Open canopies or partially/fully enclosed cladding on windward sides; ridge ventilators and louvers with bird mesh.

- Access & Safety: Transformer bays with road access, fire-safe zones, non-skid walkways, safety signage, and adequate egress widths.

(AIS = Air-Insulated Substation uses more space with visible steel gantries. GIS = Gas-Insulated Substation is compact, often requiring smaller but precise support structures and controlled enclosures.)

Structure of the Switchyard: What Gets Built

- Gantry Portals & Equipment Support Frames:

Built from rolled steel sections (I-beams/HEB/ISMB), hollow sections, channels, and angles to achieve required clearances, stiffness, and deflection limits. - Breaker/Isolator/CT/PT Pedestals:

Fabricated steel stools/base frames anchored to RCC pedestals for accurate equipment centerlines and alignment. - Bus Support Masts & Cross-Arms:

Designed for conductor tension, wind/ice loads, and insulator strings; vibration/oscillation checks as per site conditions. - Cable Trench Covers & Platforms:

Gratings or chequered plates for safe O&M; drip edges and drip flashings to keep water out. - Roofing/Cladding (if used):

GI/GL/PPGL sheets with proper laps, gutters, downpipes, and anti-bird features on openings. - Fasteners & Anchor Systems:

HT bolts, anchor bolts with templates, spring washers, and anti-loosening provisions; all selected for corrosion resistance.

Materials Used in Switchyard Structures

- Structural Steel:

Mild steel/HS sections for columns, beams, portals, and equipment stools. - Plates & Gussets:

For base plates, splice plates, stiffeners, and connection detailing. - Gratings & Walkways:

MS/galvanized gratings or chequered plates for trenches and platforms. - Roofing & Wall Sheeting:

Galvalume/PPGL profiles, translucent FRP skylights (if needed), ridge ventilators, and louvers. - Fasteners:

Zinc-plated or stainless fasteners; sealing washers for roofing; earthing lugs on primary members. - Protective Coatings:

Hot-Dip Galvanization (HDG) for primary/secondary steel; compatible touch-up systems for site cuts; epoxy systems for special cases.

Why Galvanization Is Required

Switchyards are exposed to corrosive or humid environments — coastal air, industrial fumes, frequent condensation, and dust with rain.

Hot-Dip Galvanization (HDG) ensures long-term structural reliability.

Benefits of Galvanization

- Dual Protection:

Barrier protection from the zinc coating plus sacrificial (cathodic) protection if minor scratches occur. - Long Service Life:

Decades of corrosion resistance with minimal maintenance — reducing repainting cycles and shutdowns. - Lower Lifecycle Cost:

Slightly higher upfront CAPEX; substantially lower O&M and outage costs over the structure’s life. - Faster Commissioning:

Factory-applied HDG eliminates on-site painting/curing delays and ensures consistent coating quality. - Electrical Safety Integrity:

Reliable, dimensionally stable members help maintain clearances; bolted earthing connections stay sound over time.

Good Practice:

Specify coating thickness as per environment severity, use stainless/galvanized fasteners, seal roof penetrations, and design for drainage. Apply HDG-compatible touch-up on-site cuts/holes.

Mahawar Prefab Solutions: Affordable, Durable Switchyard Structures

Mahawar Prefab Solutions (Mahawar Group) delivers value-engineered switchyard structures — from gantry portals and equipment stools to weather canopies and cladded enclosures — optimized for strength, weight, and speed.

Our Expertise

- Engineering & Detailing:

Clearances, loads, deflection checks, bay modularity, and future expansion built into the design. - Manufacturing Quality:

Precise fabrication, trial fits, and HDG/epoxy systems as per project specification. - Fast Site Execution:

Template-based anchor setting, safe crane operations, and clean cable routes. - Cost Advantage:

In-house steel capability and strict QC deliver affordable structures without compromising durability.

Partnering with Sustainability Leaders

We’ve supported companies like Terragreen by supplying engineered steel structures for their power infrastructure requirements — delivering on-time, corrosion-resistant solutions aligned with sustainability goals and rapid commissioning needs.

Plan Your Next Switchyard with Mahawar Prefab Solutions

Planning a new switchyard or upgrading an existing one?

Let’s engineer a durable, galvanized steel switchyard structure that lowers your lifecycle cost and accelerates grid-readiness.